Reactor Technology and Operating Principle

LDR (Low-temperature District heating Reactor) is a small modular reactor operating at conditions suitable for heat production without any turbine cycle. The development relies on well-established pressurized water technology, combined with passive safety design.

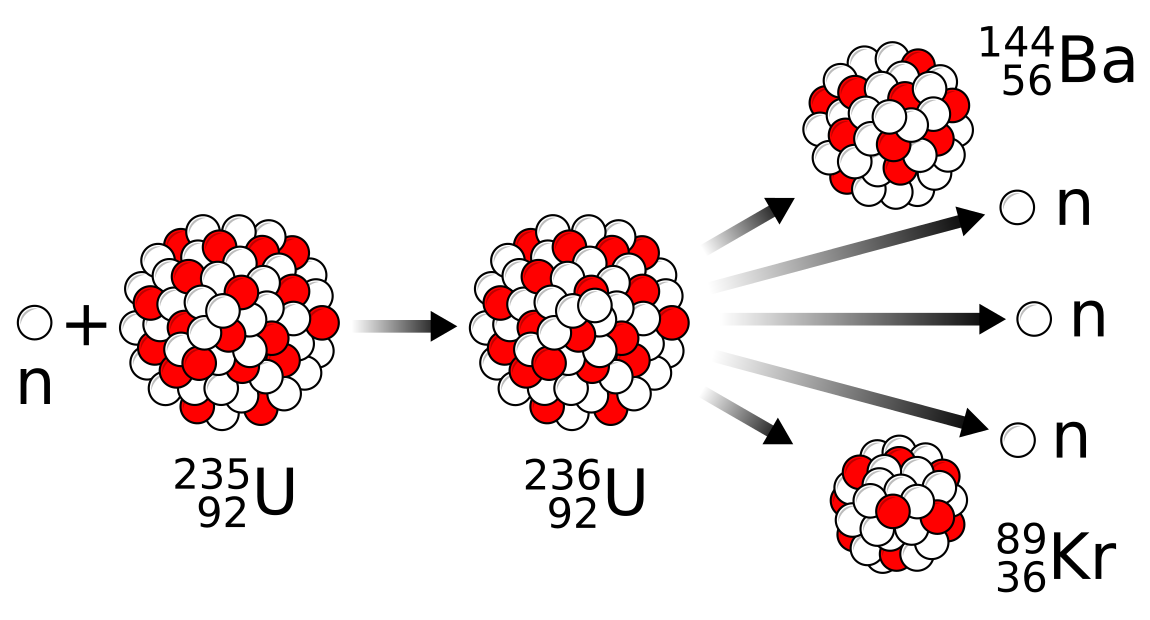

Heat is produced in nuclear fission

The operation of a nuclear reactor is based on a chain reaction maintained by neutrons. A heavy uranium atom absorbs a neutron and splits, or fissions, into two lighter fragments. The process releases energy and new neutrons, which continue the reaction chain. The energy is deposited as heat inside metallic rods that contain the uranium fuel. These fuel rods are collected into larger assemblies, which form the building blocks of the reactor core. The fission heat is transferred into coolant flowing between the fuel rods through the core.

In conventional nuclear power plants, thermal energy produced by the reactor is converted into mechanical energy in the turbine, which is connected to the generator that produces electricity. LDR, however, is designed exclusively for heat production, which means that the process does not include any turbine cycle. The reactor is connected to the district heating network via an intermediate water loop. Primary water that cools the fuel assemblies flows in a separate closed loop inside the reactor vessel, and the heat is transferred from one loop to another via heat exchangers.

Frequently asked questions about reactor operation

Low operating pressure is an advantage

In order to achieve high thermal efficiency, conventional nuclear reactors designed for electricity production operate at a temperature of around 300 °C. Similar temperatures are not necessary for heat production. Typical district heating networks operate at 65–120 °C, which also sets the boundary conditions for LDR operation.

The advantage of low operating temperature is that the reactor can also operate at much lower pressure. Coolant in pressurized water reactors flows under 150 bar pressure (150 atmospheres). In LDR, the operating pressure remains below ten bars. The conditions are closer to an espresso machine or a bottle of champagne than a conventional nuclear reactor.

The moderate operating conditions simplify reactor design. The required wall thickness for pressure vessels is only a few centimeters, which means that the components can be manufactured using conventional technology. Safety design is also simplified since accident scenarios do not involve high pressure phenomena.

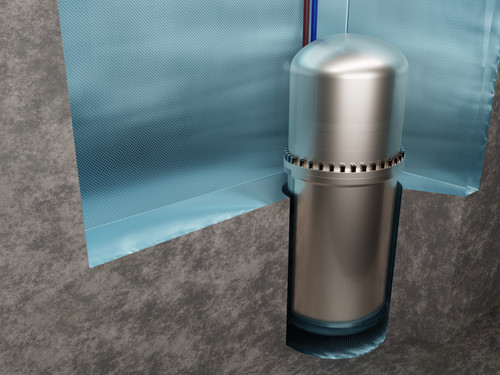

Cooling is based on natural circulation

The LDR reactor module consists of two nested pressure vessels. Coolant is heated in the reactor core, which creates an upward drift. In the upper part of the vessel the flow is directed to heat exchangers placed around the riser barrel. Heat is extracted into the secondary circuit and the cooled water exiting the heat exchangers flows to the bottom of the reactor vessel and back to the core.

The most important safety functions of nuclear reactors are related to maintaining sufficient cooling for the fuel rods, especially in situations where the normal cooling cycle has been lost. For this reason, conventional nuclear power plants are equipped with emergency cooling systems powered by back-up diesel generators. These systems are subject to high safety classifications and strict fault-tolerance criteria.

Similar systems in SMRs are often based on passive technology and natural circulation of water. This is also the case for LDR. The reactor vessel is completely enclosed inside a larger containment vessel. The reactor unit submerged in a large pool of water that acts as a heat sink. In the normal operation, heat is extracted from the reactor vessel through the primary heat exchangers into the secondary circuit, and the losses to the pool remain small.

If the normal heat removal path is compromised, temperature inside the reactor vessel begins to rise. This changes the flow conditions, initiating a passive heat transfer route through the containment space into the pool. The system does not involve any electric pumps, valves or other mechanical moving parts. The amount of water in the pool is sufficient for maintaining the passive cooling function for several weeks without any operator intervention.

Frequently asked questions about reactor safety

Video of passive cooling function in LDR:

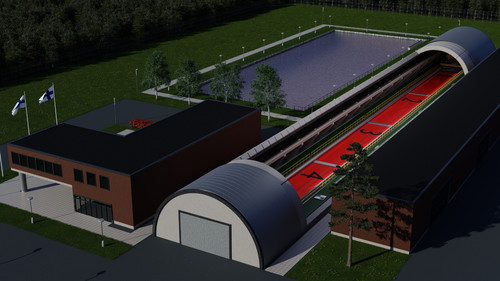

Modular district heating plant

The physical size of a single LDR-50 unit is comparable to the size of a city bus, lifted to the upright position. During its operating cycle, the reactor produces 600–700 gigawatt-hours of heat. The peak heating power is 50 megawatts, but the production can also be scaled down to meet the consumption. In baseload operation the reactor is run at full power during the cold season, and cycle length is around two years. After the operating cycle has been completed, the core is reloaded with fresh fuel. When operating at a lower power level, the fuel is consumed slower, and the reloading interval is correspondingly extended.

A district heating plant may consist of one or several independent reactor units, enabling the capacity to be scaled up. In addition to the reactor units, the plant includes auxiliary systems and technical buildings. The overall footprint of the heating plant corresponds to a small or medium-sized industrial site.

In addition to an above-ground siting option, the reactor units could also be located in an underground rock cavern. Both options are currently being investigated. Underground placement reduces the amount of concrete needed for construction, as well as the plant footprint. This can prove to be a significant advantage, as the plants are designed to be located in areas covered by an existing district heating network. Urban sites are typically reserved for other purposes.

Video of a district heating plant comprised of four LDR-50 reactor units:

LDR-50 technical specifications

| Total heat production over operating cycle | 600–700 GWh |

| Operating limits for heating power | 10–50 MW |

| Operating mode | baseload / load-follow |

| Cycle length | 24 months (in baseload operation) |

| Core inlet temperature | 80–105 ℃ |

| Core outlet temperature | 130–155 ℃ |

| Operating pressure | 0.5–0.8 MPa |

| Primary circulation | natural convection |

| Fuel material | uranium oxide |

| Fuel enrichment | ~ 2.5% U235 |

| Fuel assembly | 17×17 PWR |

| Number of assemblies in core | 37 |

| Core equivalent diameter | 150 cm |

| Core active height | 100 cm |

| Reactivity control | 37 control rod assemblies |

Figure: The fission reaction. A uranium U235 nucleus absorbs a neutron and splits into two lighter fragments. The process releases energy and new neutrons, which continue the reaction chain. Source: Wikimedia commons.

Figure: LDR-50 reactor core (right) compared to the core of a large conventional pressurized water reactor (left). Fuel assemblies are of the same type, but shorter in length. The chair is added in the illustration to provide a sense of scale.

Figure: LDR-50 operating principle. The primary circuit is enclosed inside the reactor vessel. Coolant circulates between the core and the main heat exchangers by natural convection. Heat is transferred to the district heating network via the secondary circuit.

Figure: LDR-50 reactor module submerged in a pool of water, which acts as a heat sink. The dimensions of the outer containment vessel are comparable to the size of an upright city bus.

Figure: Illustration of a district heating plant consisting of four LDR-50 reactor units. The top of the reactor building has been removed. The reactor units are placed under the red pool covers.